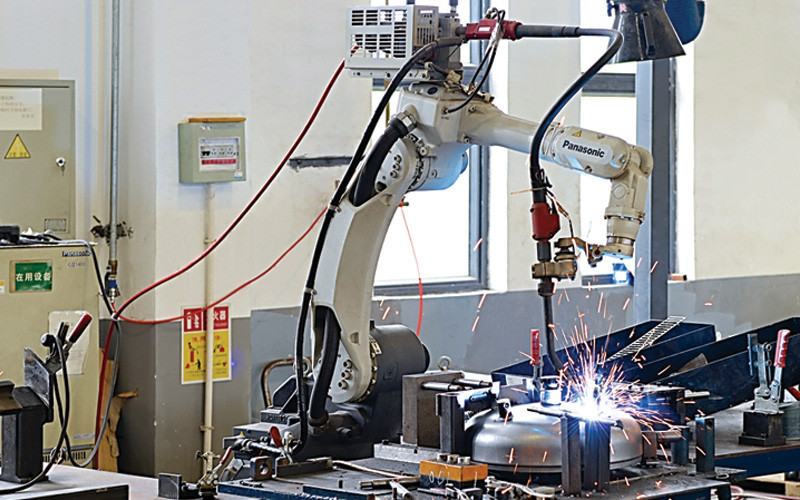

Intradin has manufacturing bases in Shanghai, Huzhou and Qingdao. The plants operate a variety of mechanical processing categories, through various forms of processing, they can meet different production requirements with priority given to in-depth manufacture of machine finishing, utilizing automation and lean production capabilities.

Intradin's management system has passed the certification of ISO9001 Quality Management System; OHSAS18001 Occupational Health & Safety Management System and ISO14001 Environment Management System.

Intradin's 3 plants all follow lean production practices. Intradin's professional lean improvement team is carrying out continuous improvement for each production link, centering on lean improvement of production of one-piece flow and replacement of labor by automated machines.

Intradin's manufacturing capacity ensures customers they will get their goods on time, at the quality, cost and safety levels that they are looking for.

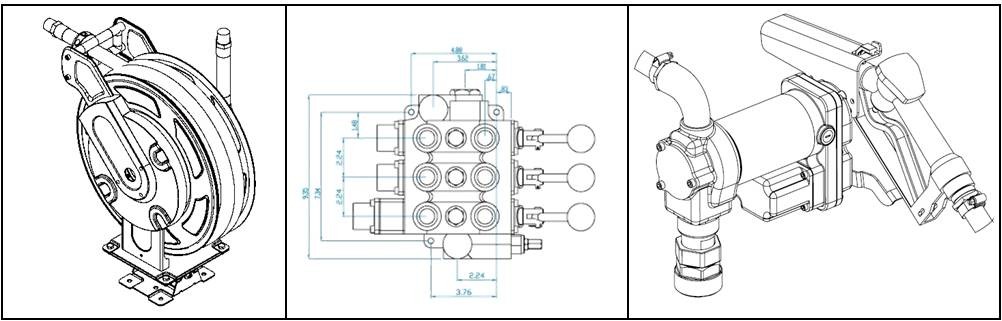

Intradin's Research & Development Center is a banner of the Company's strategic development, and an important foundation for enhancing the business professionalism of Intradin.

Intradin's Research & Development Center creates a platform for professional design and innovation. Based on the integrated working process of "research – development – design – technology – experiment", the Center develops, researches, and tests new products to satisfy requirements of quality, environment and occupational health & safety systems.

Intradin's Research & Development Center's mold production capabilities makes it easy for Intradin to make quick samples to provide measurable data for quality assurance of new product development and manufacture real products in a timely manner.

At the same time, taking advantage of external professional design teams, the Intradin's Research & Development Center conducts directional and prospective studies related to products, changing technologies, and market demands. Intradin's product Research & Development level shortens cycle of new product launches to seize market opportunities and enables Intradin to provide after-sales service and technical support for integrated solutions of product R&D.

Attaching great importance to protection of intellectual property rights, at present the Research & development Center has applied for over hundreds of domestic and foreign patents in total.